Foil Adapter Wholesale | Best Hydrofoil Customized Manufacturer

We can customize high-quality foil adapters for you to fit various foil brands. Just provide the design, and we can tailor it for you with a fast turnaround! With 9 major steps and 36 production processes, we ensure that your product will meet your customer’s expectations.

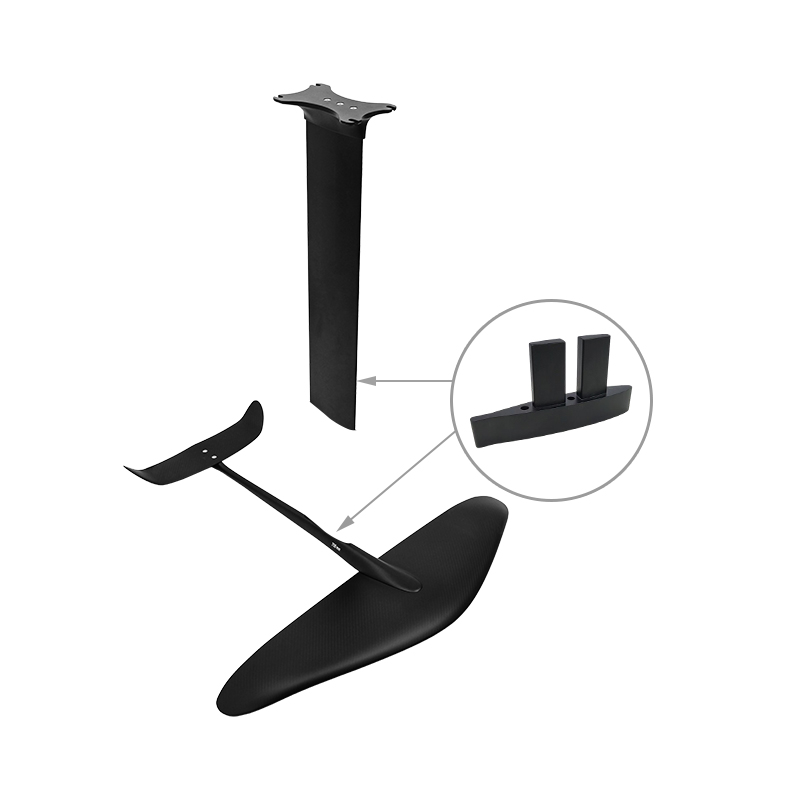

Foil Adapter Information

- Item: OEM customized

- Manufacturing process: CNC & Anodizing

- Material: Aluminium Alloy, Titanium alloy, Carbon Composite, etc.

- Fit for brands: According to your design

- MOQ: 1 for sample (sample price is higher than the mass production price)

- Price: Contact us

Welcome to our factory to discuss the long-term cooperative project with us.

Products Categories

Foil Adapter Description

Why Choose Us To Make Hydrofoil Adapters?

- Once you have your own foil adapter system, your users will be able to adapt it to 90% of the mainstream foil brands on the market.

- Optional anodized titanium alloy (tensile strength ≥ 900 MPa) or anodized aluminum (hardness HV ≥ 450), offering corrosion resistance to seawater that exceeds the national standard by 3 times. CNC five-axis precision machining with an error margin of <0.01 mm, and no deformation after 1 million fatigue tests.

- Front wing, rear wing, and mast are all available as separate components, increasing customer repurchase rates by 60%.

- We offer laser engraving and anodized color customization for your brand logo, helping you create an exclusive product line.

- 48-hour response time for design requirements, with support for small batch trial orders (minimum order of 50 pieces).

- 3D scanning reverse engineering, with new brand adaptation development completed within 7 days.

- Triple laboratory testing for performance verification.

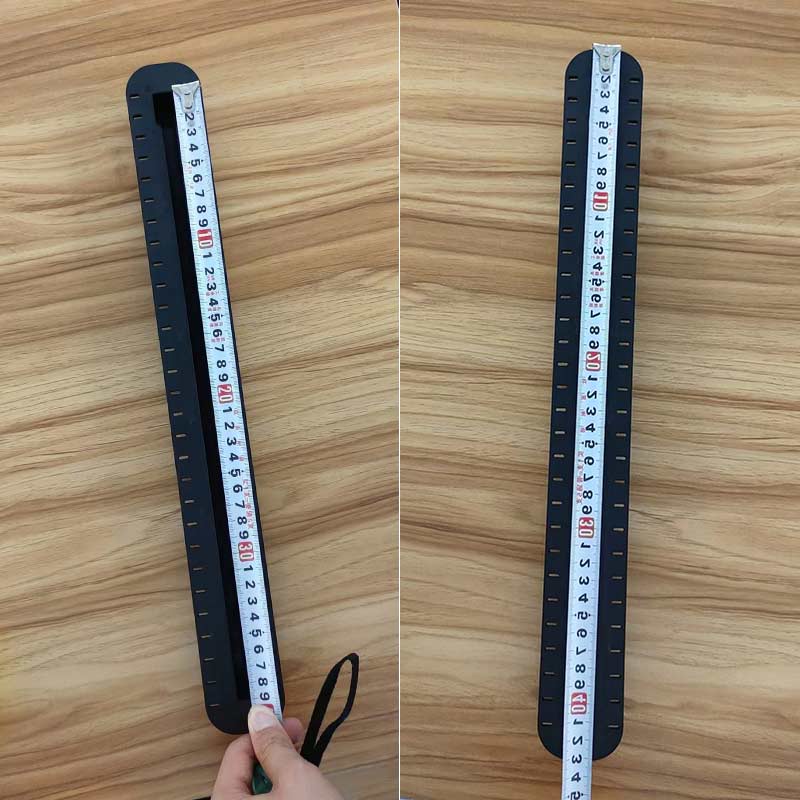

All the sizes of the adapter can be customized.

Customization Process for Hydrofoil Adapters

Step 1: Initial Consultation & Requirements

- Submit your needs via online form/email (brand compatibility, material preference, load capacity, etc.).

- Receive a free feasibility analysis within 24 hours with technical recommendations.

Step 2: Design & Prototyping

- Our engineers use your 3D CAD files to map your hydrofoil system.

- Choose materials: Anodized Titanium/Aluminum or hybrid solutions.

- Receive a quote for approval.

Step 3: Small-Batch Trial Production

- Minimum order: 50 units for functional testing.

- Optional lab certification: Salt spray/load/impact tests with official reports.

Step 4: Branding & Finish Customization

- Select:

▶ Laser-engraved logos (precision: ±0.05mm)

▶ Anodized colors (10+ standard options, custom Pantone supported)

▶ Packaging design co-creation

Step 5: Mass Production & QC

- Full-scale CNC machining with high standard tolerance.

- According to your requirements to do the QC process or use our standard.

For more hydrofoil parts, please feel free to contact us. Thank you!

Related Products