Kayak Materials: What Are Kayaks Made Of? Kayak paddlers know that the type of kayak you choose directly impacts your experience on the water. Whether you’re gliding over calm lakes, carving through whitewater rapids, or embarking on a coastal adventure, the material your kayak is made of plays a crucial role in its performance, durability, weight, and cost. Understanding the different materials available can help you make an informed decision based on your needs, preferences, and paddling goals.

In this comprehensive guide, we’ll break down the most common kayak materials, explore their unique characteristics, and help you choose the best one for your paddling style.

History of Kayak Construction

The history of kayaks is intertwined with the cultures of the indigenous peoples who originally crafted them as essential tools for survival in some of the world’s most challenging environments. The kayak, or “qayaq” in the language of the Inuit, was originally developed over 4,000 years ago by Arctic peoples for hunting, fishing, and transportation in the frigid waters of the northern seas. Understanding the materials and methods these ancient kayakers used gives us a deeper appreciation of the evolution of modern kayaks.

Kayak Origins

The origins of kayaks date back thousands of years to the indigenous peoples of the Arctic, particularly the Inuit. The earliest kayaks were crafted from organic materials like wood, bones, and sealskin, designed for hunting and transportation. These boats were lightweight, durable, and perfectly suited to the harsh environment of the Arctic.

Materials and Construction Techniques:

- Wooden Frames: The frame of early kayaks was typically crafted from wood, such as driftwood, or flexible branches of willows and birch. The frame was carefully shaped and lashed together using sinew (tendon material) or plant fibers to create a lightweight, durable skeleton.

- Bones for Strength and Flexibility: In some cases, bones from whales, seals, or other marine animals were used to reinforce the frame or to create specific parts of the kayak, like the ribs. The flexibility of the bones added strength to the frame, which helped the kayak withstand the stress of rough waters.

- Sealskin for Waterproofing: The skin of seals was the primary material used to cover the frame, as it was both waterproof and highly durable. After being cleaned, stretched, and sewn together, the sealskin was tightly wrapped around the frame, ensuring the kayak remained waterproof. The skins were sewn together using sinew or thread made from animal tendons, creating an airtight seal.

- Lightweight and Maneuverable: The design of the kayak was highly efficient for its intended purpose. The narrow, streamlined shape allowed it to move through water quickly with minimal resistance. The lightweight frame and flexible skin allowed hunters to navigate small, narrow waterways and approach prey silently, a vital advantage for hunting seals, whales, and other marine mammals.

- Size and Style Variations: Kayaks were not a one-size-fits-all tool. The size, shape, and design of the kayak varied depending on its intended use. There were single-person kayaks, which were smaller and more nimble for hunting, and larger kayaks for transporting multiple people or supplies. In some areas, larger kayaks were used for whaling, designed to carry a larger crew and hunting gear.

The Evolution of Kayak Construction

As European explorers began to reach the Arctic regions in the 16th and 17th centuries, they encountered the kayak and were amazed by its efficiency and functionality. Over time, the design of the kayak was adapted and improved as new materials and construction methods became available.

Influence of European Technologies:

- Wooden and Canvas Kayaks: By the early 20th century, European boatbuilders had begun experimenting with new materials. The Inuit-style kayaks continued to inspire design, but wooden kayaks were now built using sawed timbers instead of bone and the skin was replaced with canvas, which was more readily available and easier to work with. These early wooden-frame kayaks were typically covered with canvas that was treated to be water-resistant.

- Introduction of Fiberglass: In the mid-20th century, the introduction of fiberglass revolutionized kayak construction. Fiberglass is a lightweight, strong, and relatively easy material to mold, which made it an attractive option for mass production. Fiberglass kayaks quickly gained popularity among recreational paddlers, as they provided a good balance of performance, durability, and cost.

- The Rise of Rotomolded Plastic: In the 1970s, the development of rotomolded polyethylene (often simply referred to as “plastic”) further transformed the world of kayaking. This process allows for the creation of seamless, one-piece boats that are durable, affordable, and resistant to impact. As a result, rotomolded kayaks became the go-to choice for recreational paddlers, as they were less expensive and easier to maintain than fiberglass models.

Modern Kayak Materials and Construction

While the traditional principles of kayak design—lightweight, streamlined, and efficient—have remained constant, modern kayaks are now constructed using a wide variety of materials that are stronger, lighter, and more versatile than ever before. Advances in materials science have made it possible to create kayaks that are faster, more durable, and more specialized for different types of paddling, from whitewater to touring.

Key Kayak Materials Used in Modern Construction:

- Fiberglass: Known for its strength-to-weight ratio, fiberglass is still one of the most popular materials for high-performance kayaks. It is lightweight, resistant to cracking, and offers superior rigidity, which translates into better speed and responsiveness. The downside is that fiberglass kayaks are more susceptible to damage from impacts compared to plastic kayaks.

- Carbon Fiber: Carbon fiber is another modern material that is used in high-end kayaks. Known for its extreme lightness and strength, carbon fiber is often found in racing kayaks or in kayaks designed for expert paddlers who prioritize speed and performance. Carbon fiber kayaks are often the most expensive but are considered the pinnacle of performance in the kayaking world.

- Kevlar: Kevlar, a material often associated with bulletproof vests, is also used in kayak construction. It’s known for its high tensile strength and resistance to wear, which makes it an excellent choice for kayaks that need to be both lightweight and incredibly durable. Like carbon fiber, Kevlar kayaks are often designed for high-performance paddling.

- Thermoformed ABS and Polycarbonate: Thermoforming technology uses heat to mold sheets of plastic into kayak shapes. ABS (acrylonitrile butadiene styrene) is the most common plastic used in this process. Thermoformed kayaks are more rigid than rotomolded kayaks and have a smoother finish. They strike a good balance between performance and cost.

- Rotomolded Polyethylene: Still the most common material used in recreational kayaks, rotomolded kayak polyethylene has remained popular due to its affordability, impact resistance, and ease of repair. It’s heavier than composite kayaks but still performs well for most recreational and whitewater paddling.

- Inflatable Kayaks: Inflatable kayaks have gained in popularity, especially among adventurers and casual paddlers. Made from tough, puncture-resistant materials like PVC, these kayaks are portable, easy to store, and convenient for travel. Modern inflatable kayaks are surprisingly durable and offer reasonable performance on calm waters, though they are not as rigid or fast as hard-shell models.

Common Kayak Materials

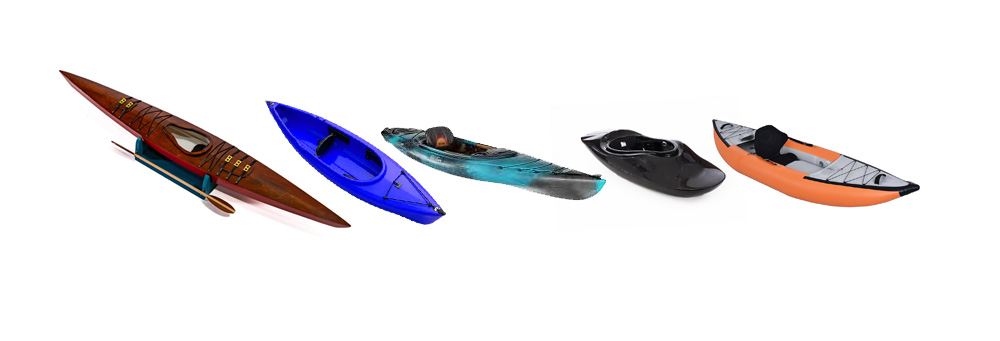

The materials used to construct a kayak significantly affect how it performs, its lifespan, and how much you’ll have to invest. Kayaks can be made from various materials, each with specific advantages and disadvantages. Let’s explore the most common kayak materials in use today.

1. Wooden Kayaks

Wooden kayaks are perhaps the most traditional form of kayak construction. These are typically custom-built kayaks that require significant time, skill, and effort to create, making them ideal for DIY enthusiasts and those who value craftsmanship. There are two primary construction methods for wooden kayaks: strip-built and stitch-and-glue.

Strip-built kayaks are made by layering thin strips of wood around a frame, resulting in a sleek and smooth finish. Stitch-and-glue kayaks, on the other hand, use pre-cut plywood pieces that are stitched together and glued in place. Both methods result in lightweight, durable kayaks that are often coated with fiberglass for added strength.

Advantages:

- Customizable design and aesthetics

- Lightweight and structurally sound

- Beautiful, traditional look

- Ideal for DIY builders

Disadvantages:

- Time-consuming to build

- Expensive if bought commercially

- Not the best choice for rocky or whitewater environments

- Requires high skill for construction

Wooden kayaks are not the most practical for everyday use, especially for paddlers who need a more affordable or low-maintenance option, but they remain a popular choice for those seeking a hands-on building project or a highly customizable boat.

2. Rotomolded Polyethylene Kayaks

Rotomolded polyethylene is by far the most common material used in recreational kayaks. Introduced in the 1970s, this plastic material is made by a process called rotational molding, where plastic pellets are melted and spun inside a mold to create a one-piece kayak. This process is simple, cost-effective, and results in a kayak that is both durable and resistant to damage.

Rotomolded polyethylene kayaks are known for their flexibility, which helps them absorb impact from rocks or other obstacles without cracking. This makes them a great choice for paddlers who enjoy whitewater kayaking or exploring rocky shorelines. However, they tend to be heavier than kayaks made from other materials.

Advantages:

- Inexpensive and widely available

- Durable and impact-resistant

- UV-resistant (though they may require a protective coating over time)

- Ideal for beginners and recreational paddlers

Disadvantages:

- Heavier than composite or thermoformed kayaks

- Susceptible to “oil canning” (a slight warping of the hull)

- Harder to repair than other materials

- Less responsive in the water due to their weight

For most recreational paddlers, rotomolded polyethylene kayaks are an excellent choice. They offer a great balance between affordability and durability, making them perfect for casual outings, beginners, and families.

3. Thermoformed ABS Kayaks

Thermoformed kayaks use a more advanced manufacturing process than rotomolded polyethylene kayaks. In this process, multiple layers of plastic (usually ABS) are heated and vacuum-formed around a mold. The result is a lighter, stiffer kayak with better performance and durability than a rotomolded polyethylene boat, but still at a price point lower than composites.

These kayaks offer many of the benefits of rotomolded polyethylene kayaks, such as durability and UV resistance, but they are lighter and more responsive on the water. Thermoformed kayaks are an excellent middle ground for paddlers who want a boat that offers superior performance without breaking the bank.

Advantages:

- Lighter and stiffer than polyethylene

- Good performance and handling

- UV-resistant and easy to repair

- Reasonably priced, offering great value

Disadvantages:

- Not as impact-resistant as polyethylene

- Can degrade over time if not maintained properly

- More expensive than rotomolded kayaks

Thermoformed ABS kayaks are great for those looking for a kayak that offers improved performance, without stepping into the high price range of composite boats. They are particularly well-suited for touring kayakers or anyone looking to upgrade from a beginner-level kayak.

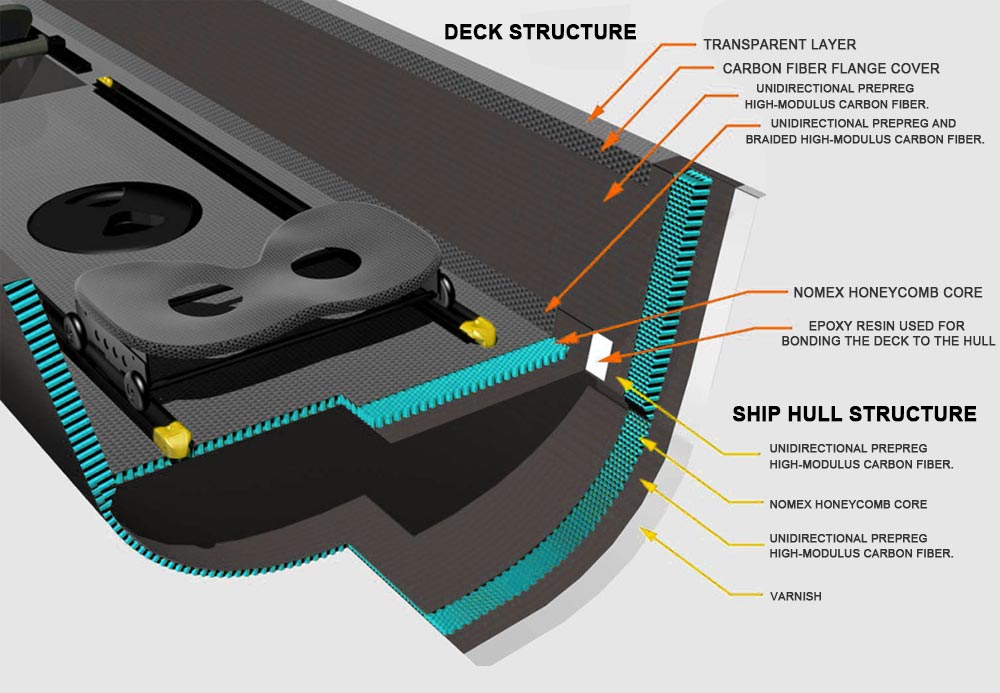

4. Composite Kayaks

Composite kayaks are made from materials such as fiberglass, carbon fiber, and Kevlar, which are bonded together using resin. These materials are incredibly lightweight and stiff, making composite kayaks the go-to option for performance-oriented paddlers. They offer excellent tracking, speed, and maneuverability, making them perfect for sea kayakers, touring enthusiasts, and even competitive racers. Suppose you are interested in composite kayak products, such as carbon kayak paddles, kayak boats, etc. Welcome to contact us for more details.

Composite kayaks are highly customizable in terms of design and are often the most attractive on the water due to their sleek, glossy finish. However, they come at a premium price and require more care and maintenance than plastic kayaks.

Advantages:

- Extremely lightweight with excellent strength-to-weight ratio

- Superior performance, especially for speed and efficiency

- Highly responsive and easy to maneuver

- Customizable design options

- More resistant to UV damage than polyethylene

Disadvantages:

- Expensive

- More vulnerable to damage from sharp impacts or direct hits (e.g., rocks)

- Requires more maintenance and care

- Not ideal for beginners

Composite kayaks are ideal for experienced paddlers who demand high performance and are willing to invest in a kayak that offers speed, efficiency, and durability on long expeditions or during competitive events.

5. Inflatable Kayaks

Inflatable kayaks are made from materials such as PVC, Hypalon, and Nitrylon, which are soft, rubber-like substances designed to withstand the high pressure of inflation. These kayaks are prized for their portability, as they can be deflated and packed away for easy storage and transport. Inflatables are often used by recreational paddlers and travelers who need a lightweight, space-saving option.

While inflatable kayaks are often thought of as being less durable than hard-shell kayaks, advances in materials like Hypalon have improved their performance, offering enhanced resistance to UV rays, abrasion, and punctures. Inflatables are also incredibly easy to repair with basic tools and patches, making them a good choice for those who want convenience and versatility.

Advantages:

- Highly portable and easy to store

- Inexpensive and generally more affordable than hard-shell kayaks

- Comfortable for leisurely paddling

- Easy to repair small punctures with patch kits

- Ideal for calm waters, flatwater paddling, or short trips

Disadvantages:

- Less responsive than hard-shell kayaks

- Susceptible to punctures and damage from sharp objects

- UV-sensitive and may degrade with exposure to sunlight over time

- Can be affected by extreme temperature changes

Inflatable kayaks are great for casual paddlers or travelers who need something that’s lightweight and portable. They’re ideal for those who mainly paddle on calm waters or lakes and want an easy-to-store kayak that can be packed up when not in use.

Which Kayak Material Is Right for You?

Choosing the right kayak material comes down to your paddling needs, preferences, and budget. Here are a few considerations to help guide your decision:

- Beginners: If you’re new to kayaking, a rotomolded polyethylene or inflatable kayak might be your best bet. These materials offer durability, ease of use, and affordability.

- Recreational Paddlers: For those who enjoy leisurely paddling on lakes or rivers, a thermoformed ABS or composite kayak may offer the right balance of performance and comfort.

- Whitewater Enthusiasts: If you’re tackling rapids or rocky environments, a durable, impact-resistant kayak made from rotomolded polyethylene or Hypalon is your best option.

- Touring and Sea Kayakers: Experienced paddlers who want speed, performance, and efficiency should look into composite kayaks made from fiberglass, carbon fiber, or Kevlar.

- Travelers and Adventurers: If you need portability, inflatable kayaks made from durable materials like PVC or Nitrylon are an excellent choice for easy storage and transport.

Conclusion

The kayak material your kayak is made of will directly influence your paddling experience, from handling and performance to durability and cost. By understanding the pros and cons of each material, you can select a kayak that best suits your needs, whether you’re a beginner or a seasoned paddler looking to upgrade your gear.

Remember, there’s no one-size-fits-all solution. Kayak construction continues to evolve, offering paddlers more choices than ever before. Take the time to evaluate the materials that match your intended use, and you’ll find a kayak that helps you make the most of every paddle stroke, whether on tranquil waters or in the most challenging conditions.

This article provides a detailed overview of kayak materials and construction processes to help paddlers understand what their kayaks are made of and how it impacts their paddling experience.