A wooden hydrofoil, in the context of water sports and boating, is a hydrofoil made primarily from wood or wooden components. The term “wooden hydrofoil” refers to hydrofoils that are constructed using wood as a primary material, particularly for structural components such as the wings, fuselages, and the mast.

Because wood is not only the material for hydro-foil, we will also tell you the materials can make a foil.

Hydro-foil Materials

Hydrofoils are typically made from a variety of materials, with the choice of material depending on the specific application and requirements. Hydrofoils are used in various marine and aerospace applications, including boats, ships, and aircraft, and the material selection is influenced by factors such as strength, weight, corrosion resistance, and hydrodynamic properties.

Common materials used in hydrofoil construction include:

- Aluminum: Aluminum alloys are often used for hydrofoil construction due to their lightweight nature and corrosion resistance. They are relatively easy to work with and are commonly found in small to medium-sized recreational hydrofoils.

- Stainless Steel: Stainless steel is chosen for its corrosion resistance and strength. It is often used for hydrofoils in saltwater environments. The added weight of stainless steel can be a drawback in some applications.

- Titanium: Titanium is a lightweight and strong material with excellent corrosion resistance. It is often used in high-performance hydrofoils, particularly those used in saltwater environments.

- Carbon Fiber Foil: Carbon fiber composites are a popular choice for high-performance hydrofoils, such as those used in racing sailboats and hydrofoil kiteboards. Carbon fiber is lightweight and offers excellent strength-to-weight ratios. It can be molded into complex shapes to optimize hydrodynamic performance.

- Fiberglass: Fiberglass composites are sometimes used for hydrofoils, particularly in smaller and less demanding applications. They are lighter than metals and offer reasonable strength and corrosion resistance.

- Wood: Wood has been used historically in hydrofoil construction and is still used in some custom or traditional applications. Wood can provide a classic look and may be suitable for recreational or experimental hydrofoils.

- Plastics: Some hydrofoil components may be made from high-strength plastics like reinforced thermosetting plastics (e.g., epoxy) or thermoplastics. These materials can be durable and lightweight, depending on the specific type used.

The choice of material depends on factors such as the intended use, budget, and the specific engineering requirements of the hydrofoil design. In many cases, hydrofoils are made from a combination of these materials to optimize their performance and durability for the given application.

What is a wooden hydrofoil?

It is a kind of hydrofoil that is made of wood material, which can lift a watercraft(Just like a surfboard, sailing boat, ship, and so on.) out of the water, reducing drag and allowing it to travel on the water’s surface with increased speed and efficiency.

It requires knowledge and experience in woodworking, hydrodynamics, and watercraft engineering. While wooden hydrofoils can be a DIY project for experienced enthusiasts, it’s important to prioritize safety and possibly seek guidance from experts in the field to ensure the hydrofoil is constructed and used correctly.

The Wooden hydrofoil’s Basic Components

- Wings & fuselages: These are the hydrodynamic lifting surfaces that provide the lift needed to raise the boat or watercraft out of the water. In the case of a wooden hydrofoil, these wings are often made from marine-grade plywood or other types of wood. They are typically coated with epoxy resin and reinforced with fiberglass to ensure strength, durability, and water resistance.

- Mast: The mast is the central structural element that connects the wings to the watercraft. It is also typically made from wood and can have a streamlined hydrodynamic shape. The mast plays a crucial role in maintaining stability and control.

- Mounting Hardware: Wooden hydrofoils are attached to the boat or watercraft using various mounting hardware, which can include brackets, struts, and other components. The choice of hardware may vary depending on the specific design and application.

Wooden Hydro-foils in Water Sports

- Kiteboarding: Wooden hydrofoils are used in kiteboarding to provide lift and improve performance, allowing kiteboarders to glide smoothly over the water.

- Windsurfing: Some windsurfers use wooden hydrofoils to enhance speed and control.

- Sailing: Wooden hydrofoils are also employed in some sailboats to reduce drag and increase speed, often in high-performance racing sailboats.

The Wooden Hydrofoil Advantages & Disadvantages

Wooden hydrofoils have their advantages, including natural buoyancy and affordability, but they also come with several disadvantages, primarily related to their durability, weight, and the complexity of construction. When considering a wooden hydrofoil, it’s important to weigh these pros and cons against your specific needs, budget, and the level of maintenance and care you are willing to invest in the hydrofoil. For high-performance or professional applications, alternative materials like carbon fiber may be more appropriate.

Advantages of Wood Hydro-foils:

- Natural Buoyancy: Wood is naturally buoyant, which can be advantageous in hydrofoil construction. The buoyant properties of wood can help with the hydrofoil’s initial lift when transitioning from displacement mode to foiling mode.

- Affordability: Wood is generally more affordable than many other materials used in hydrofoil construction, such as carbon fiber or titanium. This can make wooden hydrofoils a cost-effective choice for DIY enthusiasts or those on a budget.

- Ease of Shaping: Wood is relatively easy to shape and carve, allowing for the creation of customized hydrofoil designs with hydrodynamic profiles that meet specific performance requirements.

- Environmental Considerations: Wood is considered a renewable and environmentally friendly material when sourced responsibly. This can be an important consideration for those looking to minimize the environmental impact of their hydrofoil construction.

Disadvantages of Wood Hydro-foils:

- Durability: Wood is susceptible to rot, water damage, and decay when exposed to moisture for extended periods. To counteract this, wooden hydrofoils must be meticulously sealed with epoxy resin, fiberglass, and marine-grade paints or varnishes, which can be time-consuming and require regular maintenance.

- Weight: Wood is generally heavier than some other materials, such as carbon fiber or aluminum. The added weight can affect the overall performance of the hydrofoil, making it less suitable for high-performance applications.

- Complex Construction: Building a wooden hydrofoil can be a complex and time-consuming process, especially if you are not experienced in woodworking and hydrofoil design. Achieving the required precision and hydrodynamic characteristics can be challenging.

- Limited Application: Wooden hydrofoils are often better suited for recreational and experimental use, as opposed to high-performance racing or professional applications. Their weight and potential limitations in terms of strength may not make them the best choice for demanding situations.

- Maintenance: Wooden hydrofoils require regular maintenance to ensure they remain watertight and in good condition. This includes periodic inspection, sealing any cracks or damage, and reapplying coatings to protect the wood.

- Structural Integrity: The structural integrity of wood can degrade over time, especially if not properly maintained. This can lead to issues with the hydrofoil’s performance and safety.

How to make a wooden hydrofoil?

Building a wooden hydrofoil can be a complex and advanced DIY project, and it requires knowledge of woodworking, hydrodynamics, and engineering. Here are the general steps to give you an idea of the process, but keep in mind that this is a simplified overview, and you may need to consult more detailed resources and possibly work with an experienced craftsman or engineer for a successful project.

Materials and Tools:

- Marine-grade plywood for the hydrofoil wings

- Mahogany or other hardwood for the foil mast and other structural components

- Epoxy resin and fiberglass cloth for laminating and waterproofing

- Stainless steel hardware (screws, bolts, washers, etc.)

- Woodworking tools (saws, chisels, drills, planes, etc.)

- Sandpaper and a sander

- Waterproof marine paint or varnish

- Templates or plans for the hydrofoil design

- Safety equipment (goggles, gloves, respirator)

The video to build a hydrofoil:

DIY Steps:

- Design Your Hydrofoil: Start by designing your hydrofoil. You can create your own design or use pre-existing plans. The design should include specifications for the wings, mast, and other components.

- Prepare the Materials: Cut the marine-grade plywood and hardwood into the desired shapes and dimensions according to your design. Ensure that all the pieces are smooth and well-prepared.

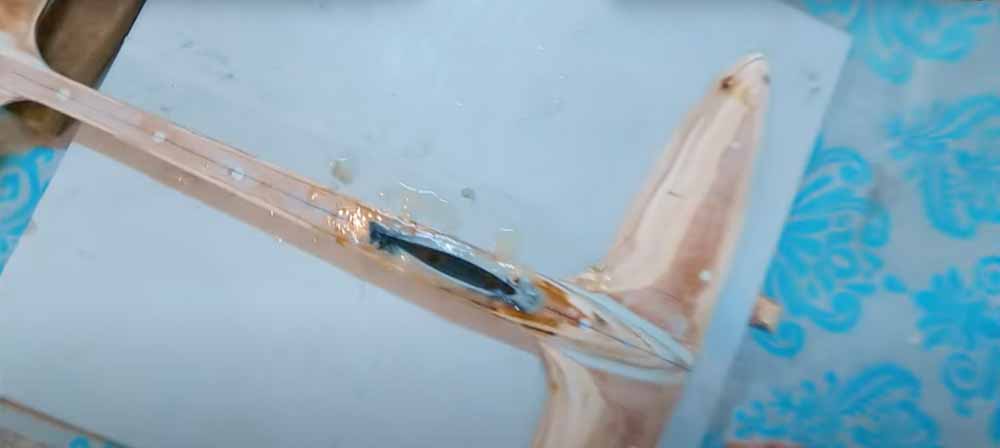

- Laminate the Foil Wings: Coat the plywood wings with epoxy resin and lay fiberglass cloth on both sides to create a strong, waterproof, and durable surface. You may need to do this in multiple layers, allowing each layer to cure before adding the next.

- Assemble the Foil Mast: Create the foil mast from the hardwood. Shape it to the desired foil section using woodworking tools. It should have a streamlined, hydrodynamic shape.

- Attach the Wings: Attach the wings to the mast using stainless steel hardware. Ensure that they are securely fastened and properly aligned according to your design.

- Build Mounting Hardware: Create a mounting system to attach the hydrofoil to your boat, board, or other watercraft. This may involve brackets, struts, or other components, depending on your design.

- Test and Adjust: Before putting your wooden hydrofoil into actual use, it’s important to test it in controlled conditions to ensure it performs as expected. Make any necessary adjustments to optimize its performance and stability.

- Finish and Protect: Sand the wood surfaces and apply a waterproof marine paint or varnish to protect the wood from water damage and enhance its appearance.

- Install and Enjoy: Finally, install the hydrofoil on your boat or watercraft according to your design and manufacturer’s instructions. Test it in the water to ensure it functions correctly.

Remember that building a wooden hydrofoil is a complex project, and safety is a priority. It’s advisable to consult with experts, do thorough research, and possibly seek professional advice or assistance, especially if you’re new to woodworking or hydrofoil design. Building and using a hydrofoil on the water also involves risks, so take appropriate precautions and consider seeking instruction or guidance from experienced hydrofoil users.